Despite a market that is deteriorating and some miners battling to survive, crypto miners are nonetheless creating cutting-edge data centers.

Popular crypto news correspondents visited bitcoin (BTC) mines in two U.S. states over the course of the summer to observe how Crypto Miners are continuing to construct data centers to support the Bitcoin network despite the current crypto winter.

Due to the sharp decline in the price of the largest cryptocurrency in the world, bitcoin, miners have had a difficult few months. Due to the low price of bitcoin, miners’ profits have decreased, and some have been compelled to sell their equipment, facilities, and even tokens they have extracted in order to raise money to maintain their operations.

In addition, the Biden administration released a report on September 8 pushing for industry guidelines to reduce the environmental impact of cryptocurrencies. If these fail, the research advised that authorities and legislators in the U.S. take action to restrict or do away with the energy-intensive proof-of-work algorithms that bitcoin miners rely on to power the Bitcoin network.

Still, Crypto Miners are hard at work expanding their capacity. Visiting these sites demonstrates how the American economy is always evolving. Depending on the region and available energy supply, mining data centers come in a variety of sizes and designs. Miners have been at the forefront of experimenting with numerous cutting-edge variations of data centers that are used for other things as well, including immersion cooling.

The network has benefited from these buildouts since computer power has been constantly increasing over the past few months.

Washington-based Merkle Standard and Bitmain facilities

A 30-year-old paper mill that has been shut down since 2020 is located close to the border between Washington State and Idaho. Although it is located near a river and has its own water treatment facilities, the area is sparsely populated with homes. You might not expect to discover a bitcoin mine testing some of the most cutting-edge mining equipment anywhere, but there it is.

The facility is a joint venture between Bitmain, the largest producer of bitcoin mining equipment in the world, and private Crypto Miners Merkle Standard. During a site visit, Merkle Standard Chief Working Officer Monty Stahl informed CoinDesk that the site is currently limited to operating at 100 megawatts (MW), roughly the annual capacity of 10 homes in the U.S., and has the electrical infrastructure to reach 225 MW.

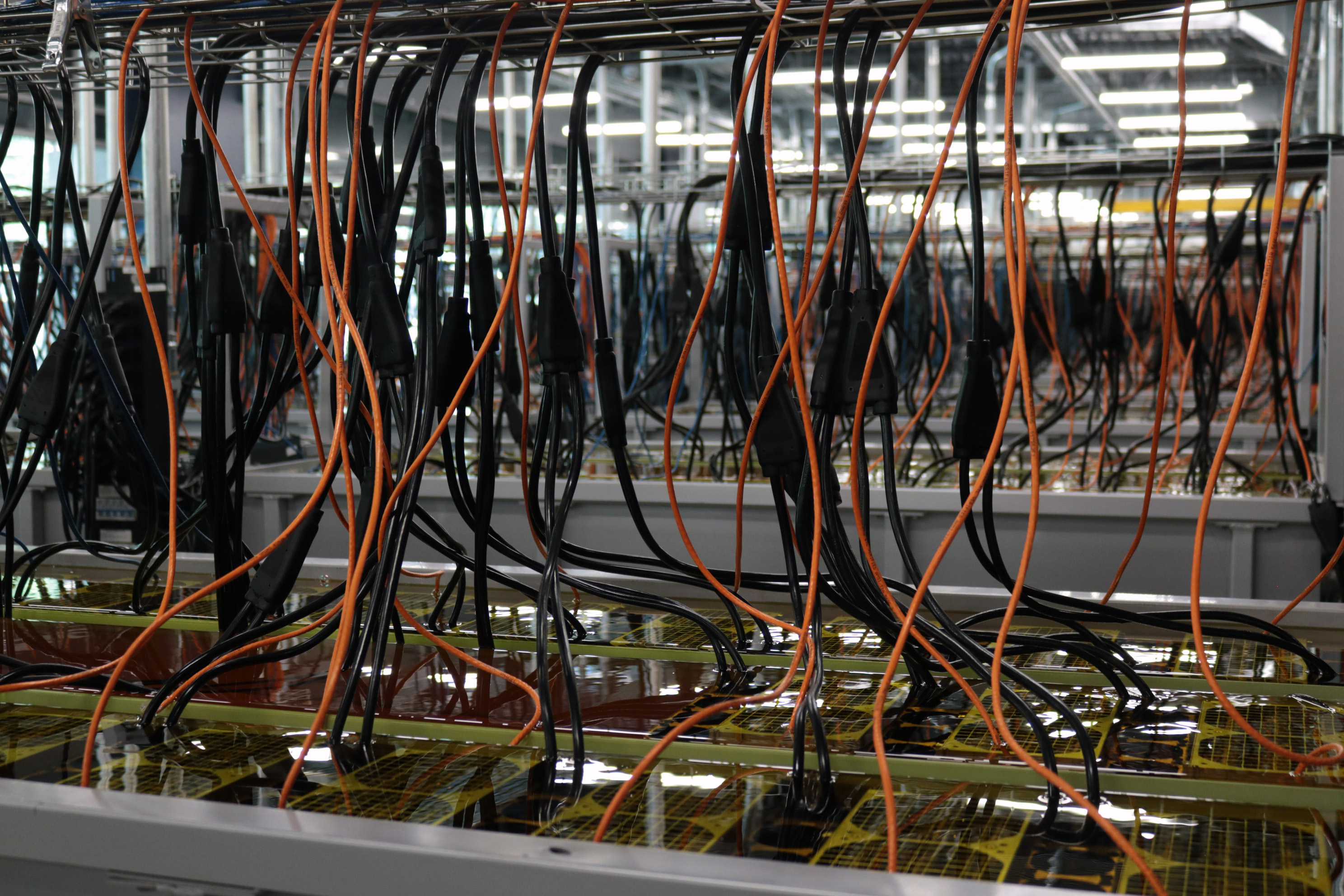

The water treatment plant is not a supplemental item. The location serves as a testing area for Bitmain’s S19 XP Hydro mining device, which uses water pipes to cool its CPU processors.

Stahl added that in order to operate these devices, “you need to understand and respect water chemistry.” He continued, “The key to the durability and efficiency of these expensive rigs is operating them with the appropriate kind of water.”

Since the chips aren’t buried in chemical mixtures, Stahl believes that this approach is better and more scalable than immersion.

The site manager is also proud of the trade skills he learned working in the mill. He claimed that he frequently finds himself in awe of the actions taken by the staff at the water treatment facility.

However, the majority of the mining is done in Bitmain’s Antbox mining containers, which are located outside the paper mill. These are former cargo containers that now house mining equipment. The paper mill has been maintained, and Merkle Standard intends to reopen it. There were 150 people working there, he observes.

Steps echoing as you move through the paper mill’s eerie hallways, it feels like something out of a horror film. Time halted when the paper mill shut down in 2020 owing to insolvency, but it never resumed. A few elements in the environment serve as stark reminders of the people who are no longer there, including a microscope that is upright and ready to be used in the lab, a plaque commemorating the production of the one-millionth ton of newsprint in 1994, and a board listing the employees who have worked there the longest.

Working here every day and being reminded of what this institution has meant to previous generations of employees is “humbling,” according to Stahl.

Georgia’s CleanSpark, Atlanta region

In the middle of the last decade, CleanSpark (CLSK), which was originally started as a software company in the late 1980s, became an alternative energy company. Two sites in Georgia show its development as a bitcoin miner.

A 47 MW bitcoin mine split into four pieces is located in College Park, close to Atlanta’s Hartsfield airport, the busiest airport in the world by passenger volume.

The location used to be a conventional data center with roughly 50 clients, who have been gradually departing the structure. There are around six left, including College Park. According to Zach Bradford, CEO of CleanSpark, after they go, the structure will be outfitted with immersion-cooled Crypto Miners. To keep the machinery cool, the structure uses what appears to be air-conditioning technology; cold air is forced via vents placed in front of the racks where the mining rigs are housed.

Another evaporation-cooled bitcoin mine is located right next door. This structure has one wall that is a perforated, wet wall that allows air to enter through it before cooling as it passes through the water, which then evaporates. Fans that draw air into the space are mounted on a different wall. The temperature of a surface decreases when water vapor leaves it, just like when you perspire while running. The business claims that it intends to eventually replace this system with another evaporative cooling system.

A few Bitmain AntBoxes mining containers, which function similarly to the evaporation cooling building, are situated outside the structure. Their back walls are furnished with cardboard-like material streaks where the steam enters.

The last component of the College Park plant that the CleanSpark team is most proud of is a set of air-cooled containers that run outside a two-story building that the business developed. The corporation constructed a sound-reducing wall and planted trees around this structure because it is the loudest area of the site.

As one moves through the “Clean Block,” as the business puts it, the temperature changes every few seconds. Cool air enters one side of the container while hot air emerges from the other. It’s similar to browsing a supermarket with a door to the freezer open in one aisle and a hot lamp quickly heating food in the next.

CleanSpark’s newer plant is located in Norcross, about 40 minutes away. The mining rigs are “immersion cooled” by submerging them in mineral oil in large tanks while having their fans removed. The liquid rises, overflows over, and is channeled into a cooling system as it becomes hotter due to the heat of the machinery.

Matthew Schultz said, “It’s like being in a spa instead of loud fans.” He wasn’t mistaken. The mineral oil pouring does resemble a quiet indoor fountain in terms of sound.

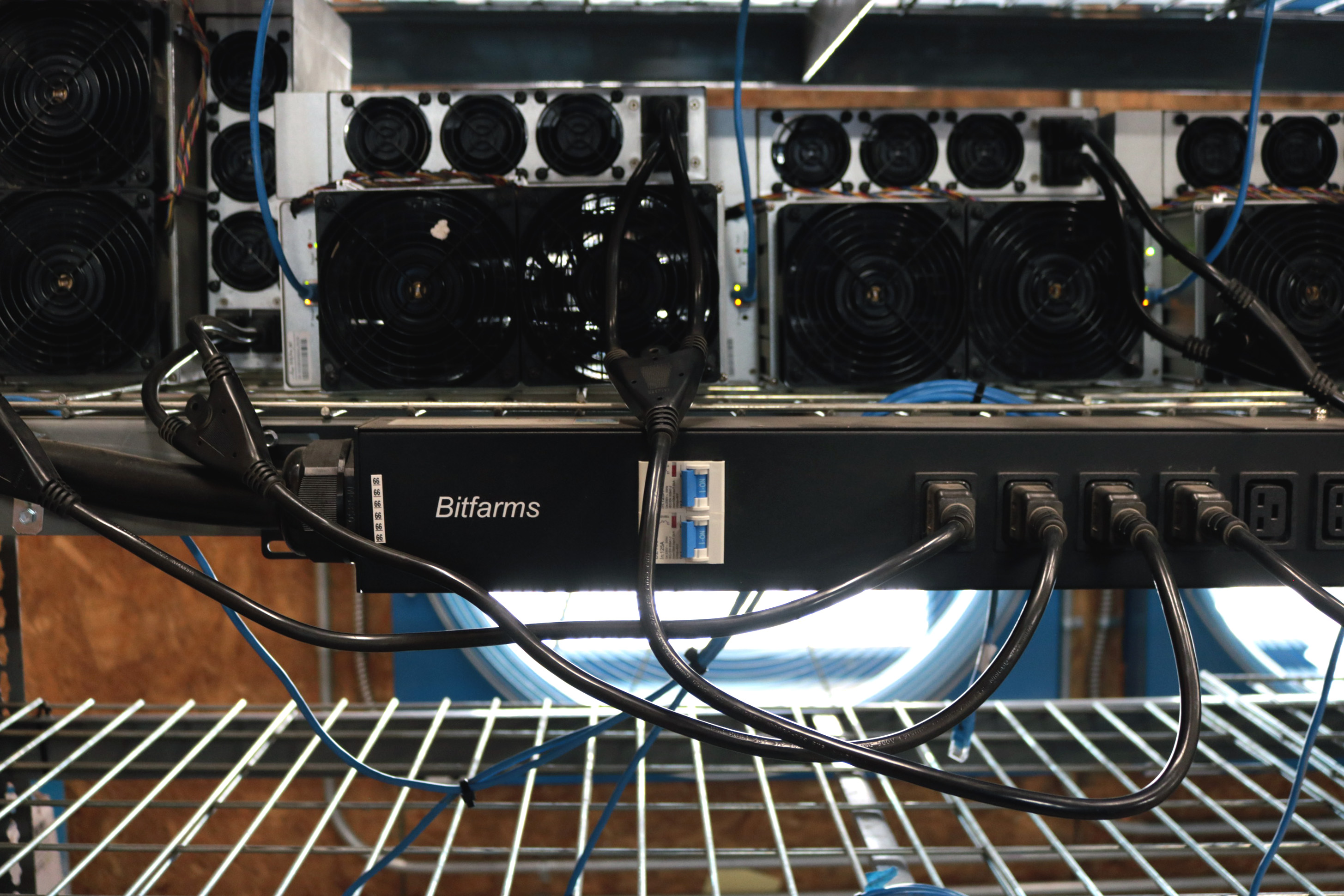

Bitfarms, Moses Lake, Washington

It’s an ancient semiconductor plant, Jayden Perry exclaimed with excitement. In Moses Lake, Washington, the manager of the Bitfarms (BITF) sites was pointing to what appeared to be a steel and concrete monster dozing in a golden wheat field, just beside one of the Bitfarms facilities. In Washington’s rural heartland, the amiable regional manager acknowledged that he enjoys learning about long-gone industrial enterprises.

In November 2021, the Canadian mining business acquired two locations from an unnamed source, and it is currently renovating them to meet Bitfarms’ requirements. Since the majority of the year is cool in this region of the country, the sites are entirely air-cooled, which means they employ sets of fans and the outside air to maintain a low temperature. Changing and organizing the racks’ wiring is one aspect of the renovation project that will prevent the machines from being hidden by a maze of dingy cables. A different option is to set up Antminer S19J Pro miners.

The Grand Coulee dam, the largest in the United States in terms of power produced, provides hydropower to the two sites, which together have a combined 20 MW and about 6,100 machines.

Although the Bitfarms facilities aren’t the most fascinating or inventive of the lot, they are nonetheless a part of the computer network that powers bitcoin. The websites are also a sign of consolidation, a new trend that has emerged in the midst of the crypto winter. Smaller businesses are finding it harder and harder to make ends meet, forcing them to sell up their properties and opening up the market to well-capitalized businesses wanting to acquire new properties. In order to protect itself from regional hazards, the mining company is also growing across four nations, with Canada, Paraguay, and Argentina making up the other three.

While enabling a decentralized infrastructure that is transforming finance, the bitcoin miners on our most recent trip demonstrate a fact that is frequently overlooked: these facilities are merely big, loud data centers that need a lot of energy.

In a sense, miners are designing data centers, and the technologies employed in these facilities—such as cooling, wiring, and machine management—could be applied to data centers for purposes other than crypto.

Despite the fact that the Bitcoin network is in many ways structured to use a lot of energy, mining companies are naturally motivated to keep their costs low or risk losing ground in a highly competitive market. This forces businesses to experiment with new methods of developing and running data centers, such as mining in remote regions of the planet like Siberia or submerging expensive machinery in mineral oil to keep it cool.

Some miners are already attempting to diversify into other data centers, such as those processing artificial intelligence and cloud computing, such as Hive Blockchain and Hut 8, which were left out of this tale.

Your Yelp ratings or Google Maps directions may be handled in a data center that was modeled after a bitcoin mine in a matter of years.